CNC-milling

Precisely shape and cut components to meet your design requirements. With our machinery and expertise, we can create complex pockets and contours with accuracy and repeatability.

Assembly & Glueing

We offer professional assembly and glueing services. Whether you need cut-outs for electrical wiring, mounting points for inserts or custom features for special applications, we can accommodate your needs.

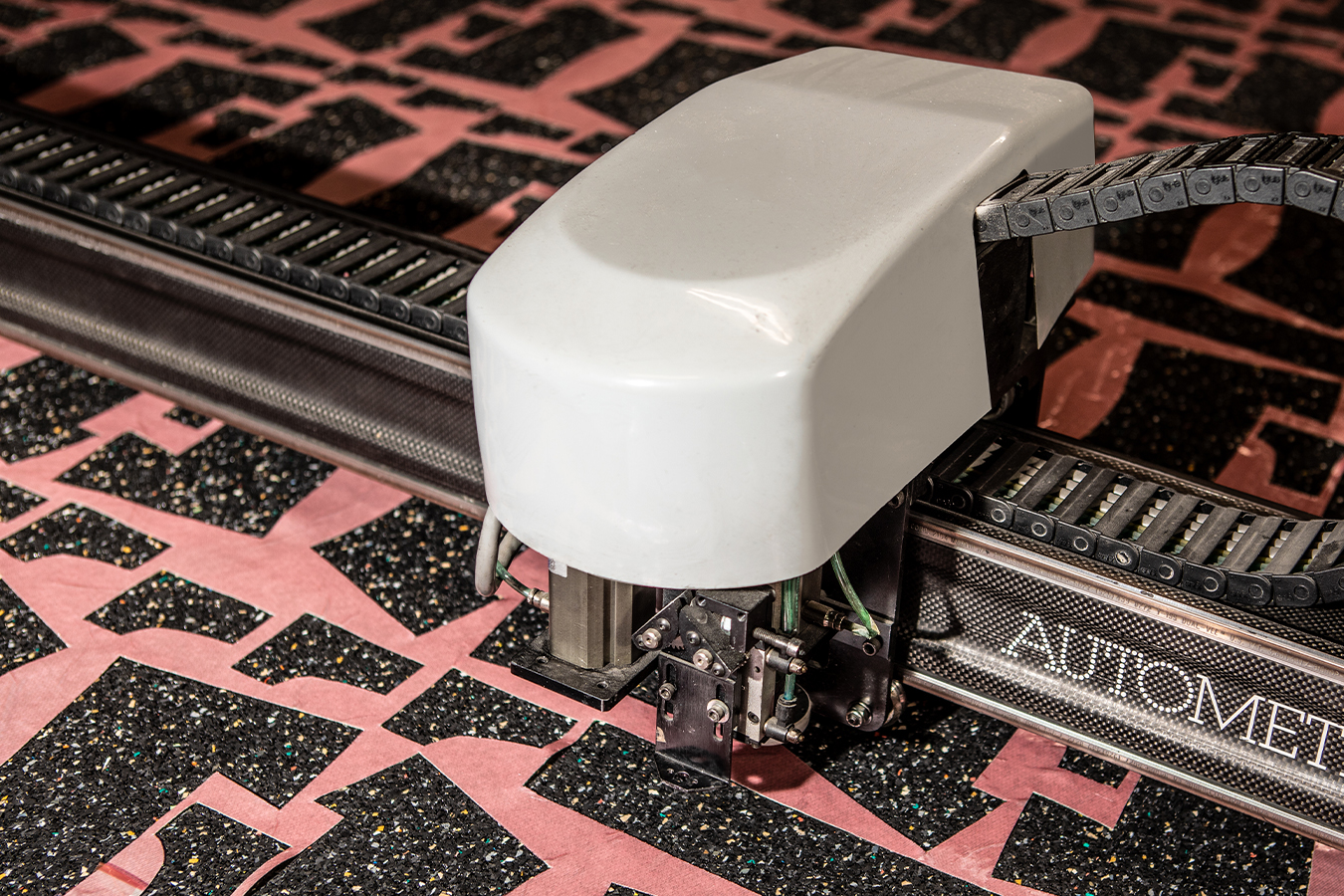

Waterjet cutting

With our high-pressure CNC waterjet cutting machine, we are able to accurately cut products with complex patterns and shapes. This cutting method ensures clean and precise cuts.

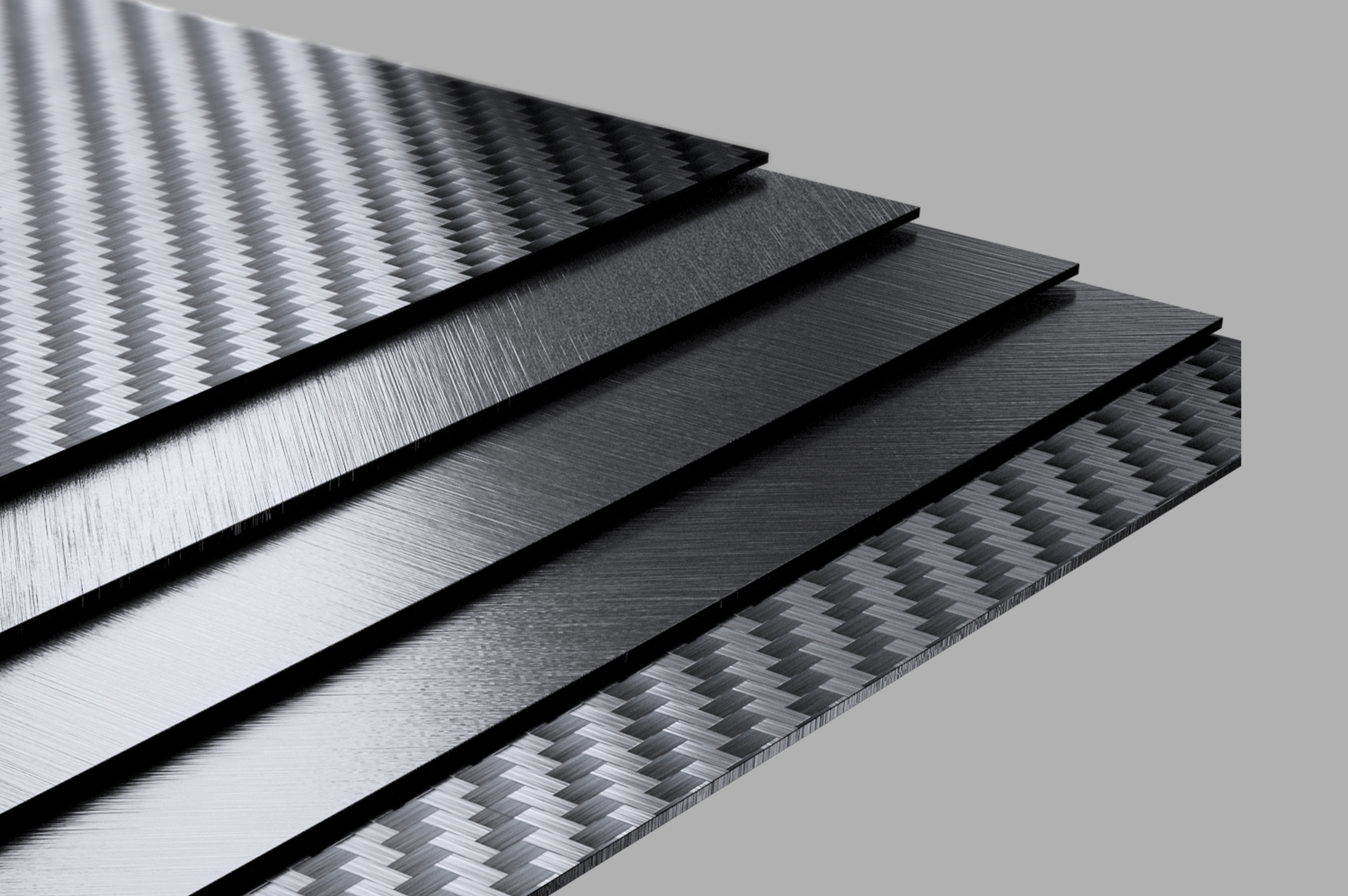

Engineering

Because the engineering rules for composites differ from those for more traditional materials such as steel and aluminium, companies often involve us at an early stage in the design of innovative products.