Refitech Composite Solutions has been around for 35 years and marks that anniversary with the launch of a new series of innovative carbon and fiberglass composite sandwich panels. The panels have a Nomex honeycomb core and are ideal when ultra-low weight is important. Applications include interiors for rail and aerospace, as well as parts of UAVs and robot systems.

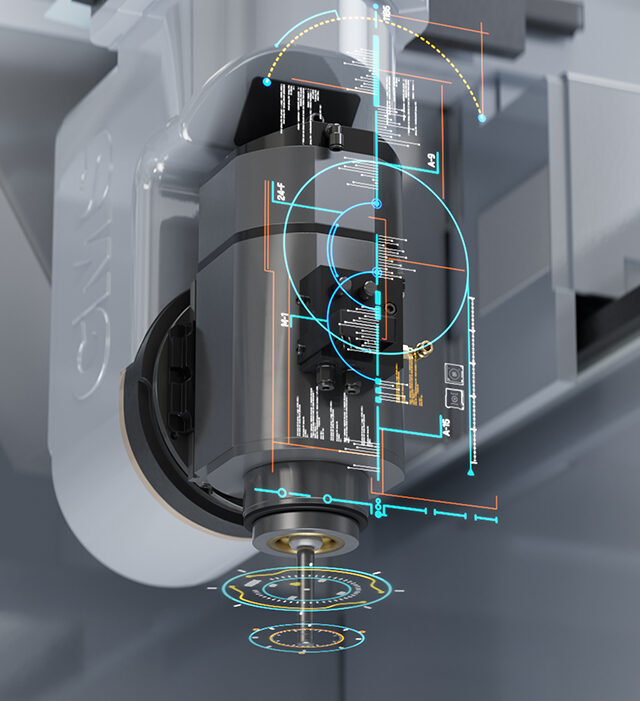

“Because we CNC-mill or cut parts with waterjet cutting, we can guarantee accurate and consistent dimensions in series,” says Bas Nijpels, Sales Manager at Refitech. “And because we produce the panels in-house, we can advise customers on the best composition for their application. Furthermore, by applying pockets, inserts and interfaces, we deliver a tailor-made, ‘ready-to-fit’ part. This saves our customers time, labor and costs.”

Over the past 35 years, Refitech has grown into a professional total supplier of composite components including post-processing and assembly for the manufacturing industry. Started in 1989 with 3 employees, the company has increased tenfold in number of employees and has a branch in the Netherlands and its own production location in China. The company’s first products were relatively simple composite parts for clap skates and hockey sticks. Today, Refitech makes 3D molded carbon and fiberglass parts for handling and production robots, medical equipment and for defence and aerospace applications. “These are all markets in which high performance is required for components. It is precisely composite that makes the difference,” explains Bas Nijpels.

In addition to the range of customer-specific parts, Refitech started in 2009 with a series of accessible and affordable standard products, including its own product line RefiFlex, which are offered via Carbonwebshop.nl. This makes it very easy for technicians, engineers and developers to independently apply innovative lightweight carbon parts, without having to invest in a mold or die. In addition to customer-specific series production, Refitech also offers solutions for small numbers and runs based on plates, profiles and connectors. “At Refitech we guide customers from a conceptual design to a serial product. We are always realistic in our advice when it comes to the use of carbon or other composites. They should mainly use it where it really has added value. By keeping the lines short, we help companies innovate with affordable carbon components that increase performance. By doing business based on mutual trust and knowledge sharing, you can move forward together,” Bas Nijpels concludes.

“At Refitech we guide customers from a conceptual design to a serial product. We are always realistic in our advice when it comes to the use of carbon or other composites. They should mainly use it where it really has added value. By keeping the lines short, we help companies innovate with affordable carbon components that increase performance. By doing business based on mutual trust and knowledge sharing, you can move forward together,” Bas Nijpels concludes.

From clap skate parts to 3D carbon components and sandwich panels.

In addition to the custom panels, Refitech also supplies standardized honeycomb panels in three different thicknesses and material composition via Carbonwebshop.com, and this for various high-performance applications. For the panels, Refitech has a specialized production department where carbon, fiberglass and aluminum sheets are combined with a foam or honeycomb core, including CNC post-processing.

“Because we CNC-mill or cut parts with waterjet cutting, we can guarantee accurate and consistent dimensions in series,” says Bas Nijpels, Sales Manager at Refitech. “And because we produce the panels in-house, we can advise customers on the best composition for their application. Furthermore, by applying pockets, inserts and interfaces, we deliver a tailor-made, ‘ready-to-fit’ part. This saves our customers time, labor and costs.”

Over the past 35 years, Refitech has grown into a professional total supplier of composite components including post-processing and assembly for the manufacturing industry. Started in 1989 with 3 employees, the company has increased tenfold in number of employees and has a branch in the Netherlands and its own production location in China. The company’s first products were relatively simple composite parts for clap skates and hockey sticks. Today, Refitech makes 3D molded carbon and fiberglass parts for handling and production robots, medical equipment and for defence and aerospace applications. “These are all markets in which high performance is required for components. It is precisely composite that makes the difference,” explains Bas Nijpels.

In addition to the range of customer-specific parts, Refitech started in 2009 with a series of accessible and affordable standard products, including its own product line RefiFlex, which are offered via Carbonwebshop.nl. This makes it very easy for technicians, engineers and developers to independently apply innovative lightweight carbon parts, without having to invest in a mold or die. In addition to customer-specific series production, Refitech also offers solutions for small numbers and runs based on plates, profiles and connectors.

“At Refitech we guide customers from a conceptual design to a serial product. We are always realistic in our advice when it comes to the use of carbon or other composites. They should mainly use it where it really has added value. By keeping the lines short, we help companies innovate with affordable carbon components that increase performance. By doing business based on mutual trust and knowledge sharing, you can move forward together,” Bas Nijpels concludes.

“At Refitech we guide customers from a conceptual design to a serial product. We are always realistic in our advice when it comes to the use of carbon or other composites. They should mainly use it where it really has added value. By keeping the lines short, we help companies innovate with affordable carbon components that increase performance. By doing business based on mutual trust and knowledge sharing, you can move forward together,” Bas Nijpels concludes.