Refitech specializes in the serial production of composite products. Composite is a plastic that is strong enough to replace steel. Refitech makes parts for medical equipment, drones, machines and sandwich panels for Air Cargo transport containers. Marcel Gillis has been full owner since 2021. His biggest goal: “The serial supply of reliable technical solutions for applications where other materials fail.”

This interview was conducted by Mr. Stefan Korthout, for Frenky Buijks – van Gool of Parkmanagement Waalwijk and is part of the series: “Ondernemer in de spotlight!” More info: www.solarisparkmanagement.nl

Composite

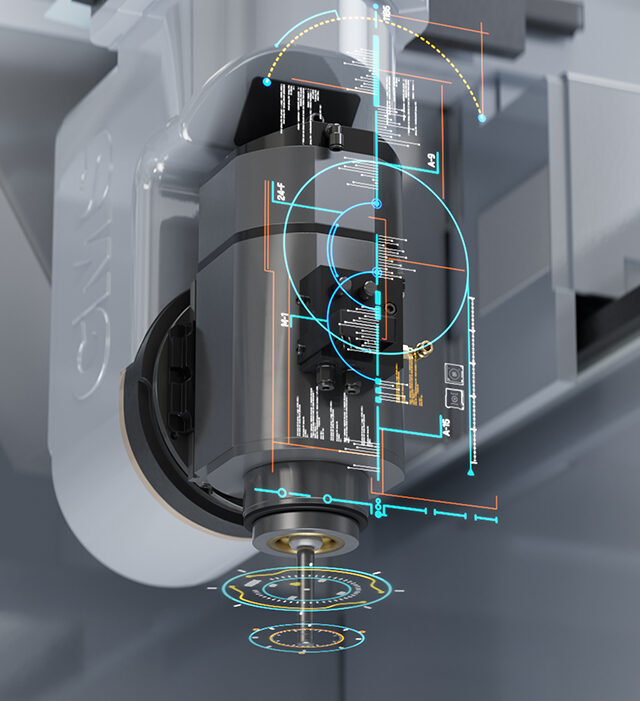

“Composite is a fiber-reinforced plastic and can be seen as an alternative to metal and aluminum. It is a composition of 2 materials, a resin matrix and a braided carbon fiber or glass fiber that is formed in a mold. These fabrics are laminated with an epoxy resin, after which the part is hardened by means of heat. Laminating is manual work and therefore quite labor intensive. During production we must take into account exactly prescribed specifications, such as the position of the fibers and the wall thickness. For the correct finishing, Refitech has a wide variety of post-processing methods that you may be familiar with from the metal industry. Think of cutting, sawing, milling, drilling and sanding. Where possible we have automated this using a 5-axis CNC machine.”

Specific characteristics

“Due to the specific properties of composite, other materials are often not a solution. The lighter a product, the less energy is needed to move something. Because composite is very strong and stiff, but much lighter than steel and aluminum, you encounter it in motorsport, cycling, drones and mechanical engineering. We make transport containers for transport by rail and by air, among other things. Chemical resistance, X-ray transparency and the prevention of material fatigue are other reasons why composite materials are chosen instead of metals. Moreover, our production method has much more freedom of form than you can achieve with metal. So we also make products that simply cannot be created in any other way.”Plastics companies

“After my master studies in Mechanical Engineering and Industrial Engineering, I worked for various plastics companies. During my internship at BMW in Munich, I discovered the advantages of plastics as a modern, future-proof material. I have supplemented this knowledge in practice through various positions in plastics production. In the meantime, I continued to look for ways to fulfill my ambitions as an independent entrepreneur. That opportunity came through a headhunter who put me in touch with Refitech and the then owner in 2011. We really clicked and there was immediate trust. We shared the same focus: the development of composite products requires an investment in time and knowledge. So if we expand this in combination with innovative customers with a serial need, we ensure healthy continued growth of Refitech. We do all our design and engineering in Waalwijk, where we have now expanded the number of product groups with the manufacture of super lightweight sandwich panels. We make the largest series of composite products in our own Chinese factory in line with European working methods and ISO standards. To make composite also accessible for smaller series in our focus markets, we have had an online carbon webshop for 15 years with standardized products for, among other things, machine and equipment construction and for use in measuring instruments and the drone industry. We offer various standard products, including pipes, plates, profiles, connectors and the adhesive to connect them.”Expansion

“We are gradually running out of space. But even if Refitech expands, we want to stay in Waalwijk, because our employees come from the region. There is a lot of knowledge and experience in the team for which no training exists. So we are careful with that. Because our suppliers and customers are located worldwide, the logistics location of Waalwijk is ideal. We will probably decide on the expansion in 2024.”

This interview was conducted by Mr. Stefan Korthout, for Frenky Buijks – van Gool of Parkmanagement Waalwijk and is part of the series: “Ondernemer in de spotlight!” More info: www.solarisparkmanagement.nl